PROJECT PROPOSAL

Brief Description of the Automated

Greenhouse (Objective):

As a

technical project I plan to design a system that will completely automate a

greenhouse. Using the C++ programming

language I plan to develop software that will monitor various conditions within

the greenhouse and perform task such as watering and cooling automatically.

Thus eliminating the need for human labour. Data will be collect and stored in

spreadsheet format file(s) and presented in graphical form through the use of

the Graphical Programming Language LabVIEW. The entire software system will be

presented as a stand-alone test executive developed with National Instruments

LabVIEW and/ or TestSTAND programming software that can be installed on any

standard Intel 80486 or higher system running Windows 95 of higher. LabVIEW

will also execute the C++ program in its own environment. The hardware portions

will be designed to connect directly to a standard IBM PC parallel port located

up to 50 feet away (standard specification).

This system will be designed to monitor both the

temperature within the greenhouse and the moisture of soil in the greenhouse.

As part of the automated process the temperature transducer will be associated

with a heating and cooling system. If the temperature within the greenhouse

exceeds a high temperature limit motorized fans will be turned on and remain on

until the temperature fall back into an acceptable range. Subsequently, if the

temperature falls below a low temperature limit a central heating system will

be turned on. The system will also have the ability to monitor the moisture of

the soil in the greenhouse to determine if water needs to be added. If the soil

moisture transducer determines that there is a lack of water in the soil it

will have the system turn on water valves for a set time to water the plants.

Proposed Design

Specifications

Interfacing Software:

As stated earlier the interface

software will be developed in the C++ environment. Using parallel port

addresses 378H (output), 379H (input), and 37AH (Bi-directional) the software

will use 8-bit parallel data to monitor the greenhouse and display its findings

on the screen. The system operator will set the sampling rate and acceptable

temperature range. The collected data, which will include date, time and

measured values, will all be written to a spreadsheet file at the time of

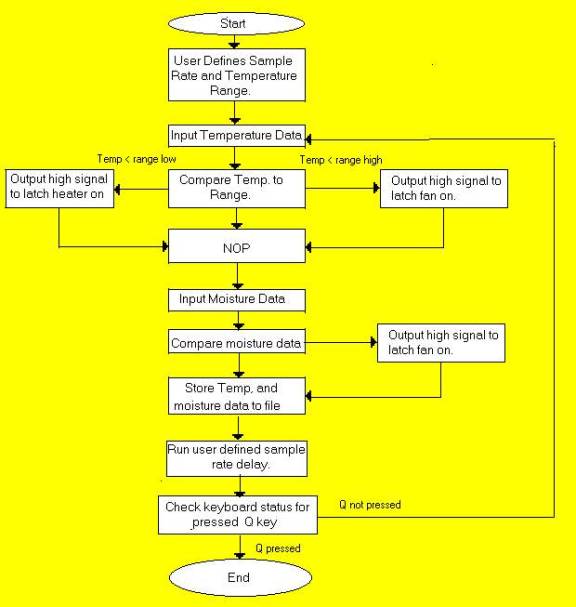

sampling. A simplified flowchart of the program is shown if Fig. 1-1 below.

Fig. 1-1: Program Flow Chart

LabVIEW Software:

LabVIEW

will be used to develop a complete windows based test executive. This program

will provide security features such as password protection to the system. Only

authorized operators will be able to start up the test plan. Furthermore,

LabVIEW will be used to execute the C++ program and display the acquired data

stored in the spreadsheet file whenever the operator wishes to do so. The

display will consist of graphs, tables, and charts.

Hardware:

The

hardware consists of a fan, heater, thermistor, soil moisture transducer, light

bulb (to simulate watering system), and various other discrete components. To

the analog signals from the transducers will be signal conditioned to produce

0-5VDC signals and converted to 8-bit digital signals with ADC0804, 8-bit

analog-to-digital converters. Since the 80x86 PC only allows 8 bits of data

to be inputted at a time a 74157 multiplexer will be used to input the

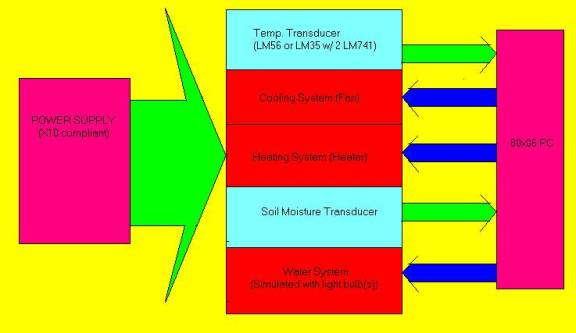

digital signal 4-bits at a time. Fig. 1-2 below shows a conceptual block

diagram of the overall circuit.

Fig. 1-2: Conceptual block diagram

Temperature

Transducer: Currently I have chosen to use the LM56 IC as a temperature-sensing device because it is capable of

measuring temperature in a range of –50 to +100 degrees Celsius. Furthermore

the LM56 IC contains two operational amplifiers

that can be configured as a window comparator to set the upper and lower

temperatures. If however This IC cannot be obtained I will resort to using a LM35 thermocouple and two LM741 op-amps to do the same thing. Further details of this signal

conditioning will be shown in future updates.

Soil

Moisture Transducer: Various soil moisture

transducers have been researched but I have yet to find one in my price range.

Research has indicated that one alternative is to use two electrodes and

measure the resistance of dry soil and highly saturated soil and uses this as a

linear relationship for signal conditioning purposes. Additional research is

underway and this area will be updated shortly.

Cooling

System: To reduce cost a large

computer-cooling fan will be used rather then an industrial or residential one

that would be used in an actual greenhouse. The fan will be connect such that a

short hi pulse from the PC will latch it into operation and it will remain on

until the program checks the temperature again. At that time, if the temp. is

still to high the fan will remain on. If the temp falls back into range the fan

will be turned off.

Heating

System: Once again a small heating element

will be used to produce heat rather then an industrial or residential one that

would be used in an actual greenhouse. The heater will be connect such that a

short hi pulse from the PC will latch it into operation and it will remain on

until the program checks the temperature again. At that time, if the temp. is

still to low the heater will remain on. If the temp rises back into range the

heater will be turned off.

Watering

System: A small light bulb will be used to

simulate the watering of plants. I plan to use a LM555 timer to keep the water

(light bulb) running for a 30 seconds before it cuts off.

Construction

This

system is to be designed as a practical consumer product. For this reason I

plan to package it in an enclosed case. The circuit will be constructed on

either a wire wrap board or a PCB. If I can gain access to the facilities

required to make a PCB we will use a PCB development program such as OrCAD or

Electronic Workbench 6: Ultiboard.

Cost

I expect

the cost of this project including the production stages to be in the range of

$150 - $200.

Demonstration

Currently

I plan to use my notebook computer to run all software and connect hardware

directly to it.

Project

Schedule

|

Week of |

Scheduled work |

|

May 11,

2001 |

-

First Class -

Order evaluation software

from Nation Instruments |

|

May 18,

2001 |

-

Submit project proposal

(objective, goals, and timeline). -

Block outline and

conceptual circuit -

Start Ordering Parts -

Start C++ Program. |

|

May 25,

2001 |

-

Determine all parts and

order them. -

Continue with C++ program

and start LabVIEW program. -

Work on hardware design. |

|

Jun. 1,

2001 |

-

Complete C++ program -

Complete LabVIEW program -

Work on hardware design and

troubleshooting. |

|

Jun. 8, 2001 |

-

Complete hardware. -

Interface hardware, C++

software and LabVIEW software. |

|

Jun. 15,

2001 |

-

Work on construction

stages. -

Write final report and

design power point presentation. |

|

Jun. 22,

2001 |

-

Complete construction

stages before Friday. |

|

Jun. 29,

2001 |

-

Presentation. |